Triangle Climbing Walls

Unique properties

- Enormous design freedom and natural climbing lines

- All triangles are unique in shape and size and are prefab produced

- Fast assembly because off self-bearing structure

- Extreme precision thanks to CNC production process

- Winner of the Outdoor Industy Award

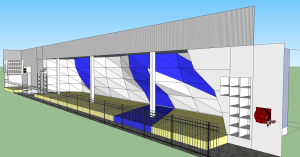

A new generation of Climbing Walls

Mountain Network has more than 30 years of experience as advisor and producer of climbing and bouldering walls. Together with renowned partner Arcadis engineering and architects Oosterhuis & Lénárd (ONL) we have designed a new generation of climbing walls. These walls are based on a triangular structure which creates an enormous design freedom. All triangles are unique in shape and fit perfectly together like a giant jigsaw puzzle. Thanks to the use of these triangular shapes, the climbing walls looks aesthetically very impressive.

The system

The digital design, in combination with a computer controlled CNC production process guarantees a seamless precision in the final product. On top of that the computer calculates which unique triangles have a optimum fit in a single sheet of wood, so we can produce the climbing wall with a minimum waste. A further benefit is that the wall is self-bearing therefore there is no need for extra construction on the reverse side. All of this results in lower production costs and a much quicker final assembly.

Because of these innovations in production and design, the Triangle Climbing Walls won the Wood Innovation Price 2012.

Climbing walls

Because the triangle climbing walls are self bearing, they can be built on any location both indoor and outdoor. Thanks to the use of prefabricated elements, this system is also very well suited for the replacements of old walls.

All prefab elements have a M12 lead climbing bolt, that is specially designed for the placement of quick draws. This bolt complies with the European EN-12572 norm for artificial climbing objects, so extra securing on the reverse side is not necessary. On the top of the wall we place a specially designed top anchor which provides each climbing line the flexibility to be used for both lead climbing or toproping.

Bouldering Walls

The Triangle Climbing system is also very well suited for building bouldering walls. These walls have the same self bearing characteristics and are also prefab made. A major advantage of these bouldering walls is the fact that they are easy to dismantle and rebuilt. This way an entire bouldering gym becomes removable and reusable.

Design

The design of the Triangle climbing walls can be divided into two phases. In the first phase the designers from MN will create a design that matches the criteria set by the customer. In this phase there is plenty of opportunity for the customer to provide feedback and change in the design.

The initial design is then sent to the architects of ONL, who then translate it into a final design. During this process the customer will be asked to give regular feedback, so that the final design meets every expectation and requirement.

At the end of this phase the strength of final design will be calculated by the structural engineers of Arcadis, so the design conforms with the European EN-12572 norm for artificial climbing objects.

Production

Just like the design, the production process is also digitized. In production Mountain Network utilizes the latest in CNC computer controlled milling machines, which guarantees a seamless precision in the final product. All triangles are prefabricated, so only the final assembly is needed.

Because of the digital design and production the material waste can be reduced to a minimum. In combination with the use of FSC certified wood, these walls have minimal environmental impact.

Assembly

As a result of the prefab production and the lack of a sub frame, the assembly phase can be reduced to a minimum making it possible to build entire climbing gyms in weeks instead of months.

As a result of the prefab production and the lack of a sub frame, the assembly phase can be reduced to a minimum making it possible to build entire climbing gyms in weeks instead of months.

Final results

The design freedom provided by the triangles makes it is possible to create climbing walls in organic shapes. The different wall sections will be connected in a continuous flow and natural climbing lines will appear. These factors combined make the final product aesthetically very impressive.

Safety and inspection

At Mountain Network safety is of paramount importance. All our climbing walls conform to the European EN-12572 norm for artificial climbing objects. During the design process the strength of the walls are calculated by the structural engineers of Arcadis. After the final assembly all our walls are inspected by the independent body TÜV Netherlands.

Climbing routes

After assembly of the climbing wall, experienced routesetters from Mountain Network can set all the required climbing routes. Because of our 5 climbing gyms in the Netherlands, we have a large team of experienced routesetters available who can set routes in every grade, from french grade 3 until 8c.

Partners Mountain Network

• ONL: www.oosterhuis.nl

• ARCADIS: www.arcadis.com

• KLEIN DESIGN: www.kleindesign.nl

Safety

All our climbing walls conform to the European EN-12572 norm for artificial climbing objects.

All our climbing walls conform to the European EN-12572 norm for artificial climbing objects.

MN Climbing Walls

Nieuwe Kade 4

6827 AA Arnhem

- Telefoon

- +31(0)88-1236821

- climbingwalls@mountain-network.nl